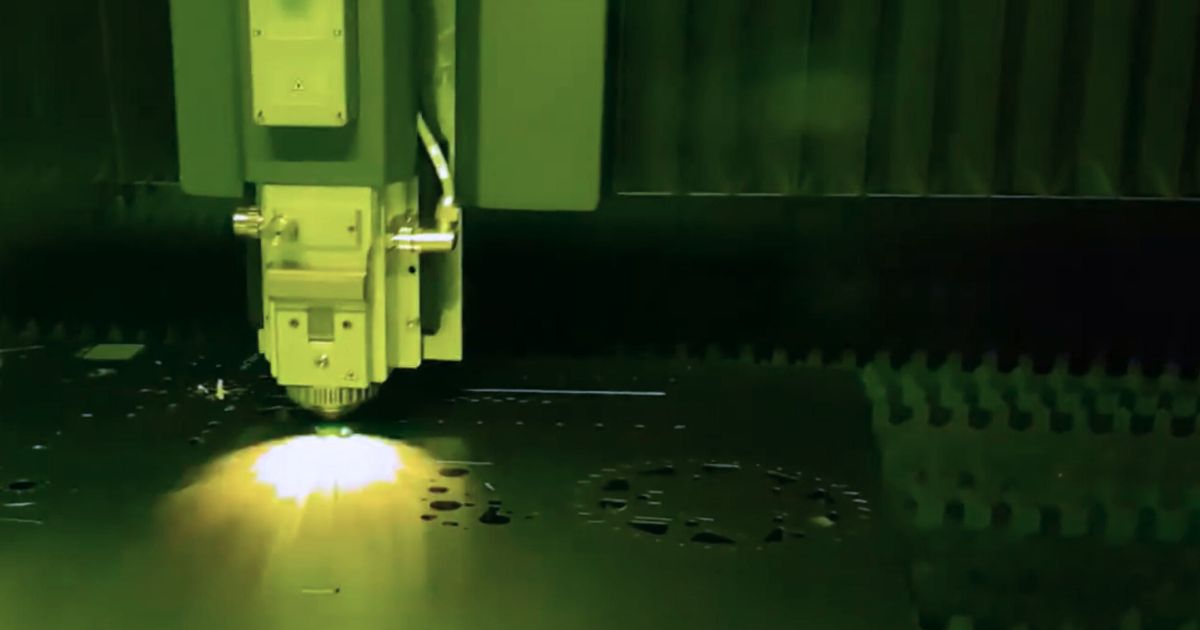

Laser Cutting Services

Our cutting service uses the most up-to-date laser equipment to transform your designs into reality. Our fibre source delivers energy through an optical fibre to a precision cutting head, which uses a focusing lens to place the beam exactly where it is needed for clean, accurate cuts.

Our processes allow us to cut complex profiles and intricate patterns with exceptionally clean edges, quickly and to a high degree of accuracy. Our strategic investment in leading laser technology ensures we meet the varied needs of our clients, from one-off prototypes to large-scale production runs. We hold tight tolerances, with repeatability to ±0.025 mm and positioning accuracy to ±0.050 mm.

Our Laser Cutting Capabilities - LVD Lynx FL-3015, 4 kW

We run the LVD Lynx FL-3015 4 kW fibre laser for high performance cutting of steel and non-ferrous materials across a wide range of thicknesses.

Advanced Cutting Dynamics

Fast contouring and clean edges on complex profiles. The Lynx FL-3015 delivers up to 120 m per minute traverse speed, so you get short cycle times on one-offs and production batches.

Precision Motion Control System

The Lynx holds specification on small features and long cuts alike. Positioning accuracy is ±0.050 mm. Repeatability is ±0.025 mm.

Siemens 840D sl CNC with Siemens servo drives and inclined rack and pinion on X and Y. Touch-L on screen makes set-ups and nesting fast.

Automatic shuttle tables are standard. While one sheet cuts, the next loads. Table change on the 3015 is 26 seconds, which keeps uptime high.

Smart Factory Ready

Versatile Sheet Handling with the Lynx Series

Bed size, 3050 × 1525 mm

Power, 4 kW IPG fibre

Cutting head, Precitec ProCutter, auto focus, 200 mm lens

Max traverse speed, 120 m per minute

Positioning accuracy, ±0.050 mm

Repeatability, ±0.025 mm

Table change, 26 s

Max sheet weight, 750 kg

Why Choose LDJ Sheet Metal?

LDJ Sheet Metal Engineering delivers high-precision cutting, forming and fabrication services tailored to your project needs.

Unmatched Precision

Leveraging advanced laser optics and CNC motion control, we achieve intricate designs and consistently hold tight tolerances, delivering parts that meet your exact specifications.

Speed & Efficiency

The high-speed capabilities of our LVD Lynx fibre laser, combined with quick setup times, mean faster turnaround for both one-off prototypes and large-volume production runs.

Material Versatility

We expertly process a wide range of materials including mild steel, stainless steel, aluminium and copper, utilising the optimal laser technology for each.

Design Flexibility

We can work from your DXF files, full CAD drawings, simple sketches, or even physical templates to bring your concepts to life.