Sheet Metal

Fabrication

LDJ Sheet Metal Engineering provides a comprehensive range sheet metal fabrication services, turning raw material into precise, fully-formed components. We combine advanced machinery with skilled craftsmanship, we deliver high-quality, ready-to-assemble parts that meet the demands of diverse industries.

Complete In-House Fabrication Capabilities

- Shearing and guillotining

- CNC punching and profiling

- Folding and forming

- Notching and cropping

- Welding and assembly

Fabrication Equipment at a Glance

- Safan Guillotine (3000 x 4mm) – High-accuracy shearing for clean, straight cuts in mild steel, stainless, and aluminium.

- Geka 45 Minicrop – A robust ironworker for cropping, punching and general fabrication tasks.

- Brake Presses Promecam, Amada) – For bending and shaping components with precision.

High-Accuracy Forming with Amada Press Brake

Our Amada HFE3ipress brake brings digital accuracy to every fold. CNC control with automatic angle correction ensures perfect results from first bend to last. Capable of intricate geometries and heavy-duty folds

Precision Cutting with SafanDarley B-Shear

Our SafanDarley B-Shear delivers the accuracy that defines the start of every project. Using hybrid electronic-hydraulic technology, it cuts sheet metal cleanly and quietly with fine-tolerance control of 0.01 mm.

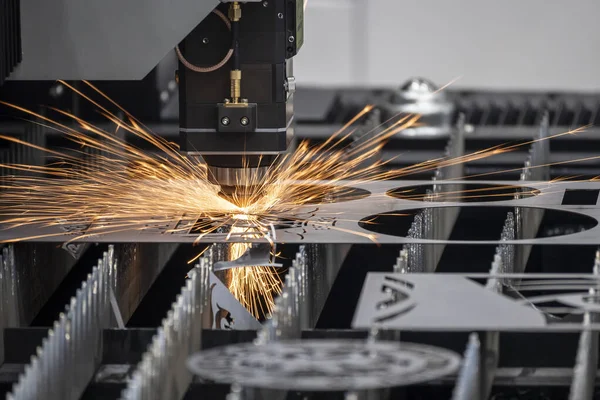

LVD Phoenix 3015 Fiber Laser

Our LVD Phoenix Fiber Laser delivers precise, high-speed cutting across all metals. Its advanced fiber source and CNC control ensure consistent edge quality, minimal waste, and repeatable accuracy on every job.

SafanDarley B-Shear: Precision Cutting for Quality Results

SafanDarley B-Shear

Precision Cutting for Quality Results

Our SafanDarley B-Shear delivers the clean, accurate cutting needed to produce top-quality fabricated components.

Using advanced hybrid electronic-hydraulic technology, it combines quiet operation with consistent precision across every sheet.

Fine-tolerance accuracy

Automated blade clearance control maintains cutting precision within 0.01 mm, ensuring clean, repeatable results.

Superior edge quality

Smooth, burr-free edges reduce or remove the need for finishing, saving time before welding or folding.

Lower project costs

Energy-efficient drive technology and minimal material waste support competitive pricing and sustainability.

Large-format capability

Pneumatic sheet support ensures accuracy and surface protection when cutting large or heavy sheets.